- shape and dimensional variability

- product strength and rigidity

- self-extinguishing ability

- colour finish surface according to RAL scale

- choice of surface – imitation concrete, high gloss or matt component

- surface hardness

- hygienic safety

- thermal insulator

- non-magnetic

- chemically and mechanically resistant

- low maintenance costs

- weatherproof

Covers

The manholes are supplied with covers with load class B 125 and D 400. The cover lids are made of cast iron and are housed in steel frames. The covers in class B 125 are installed directly on the manhole body. According to the installation instructions, concrete needs to be poured under the D 400 class covers to form a concrete lifting ring to ensure the required mechanical strength. The covers are designed for load class D 400 in a travelling surface environment. They are not intended for heavy traffic in exposed locations.

In-paving covers can be supplied if required – the lids and the perimeter of the manhole are fitted with stainless steel frames at the required height (according to the paving used).

Frames

The solid frames for ZEKAN covers have been oversized so that they can be used together with the covers even in the most demanding conditions. The frames are simply joined with a proven 8-point fastener system and the option of fixing with a construction bonding agent to ensure the joint is permanent. The frame design allows for customised cover assemblies starting with the smallest 335 x 600 clearance solution, with no upper limit, only depending on the specification of the installation.

Covers

The material for the production of covers is self-extinguishing, dimensionally stable, has high surface hardness, is hygienic, thermally insulating and non-magnetic. The covers can also be machined with conventional metal tools.

The cover locking is solved in the standard version by means of a screw with metric thread and threaded sleeve mounted in the manhole body. It is possible to select a version with a classic M10 hexagon head screw or SECURITY TORX screws

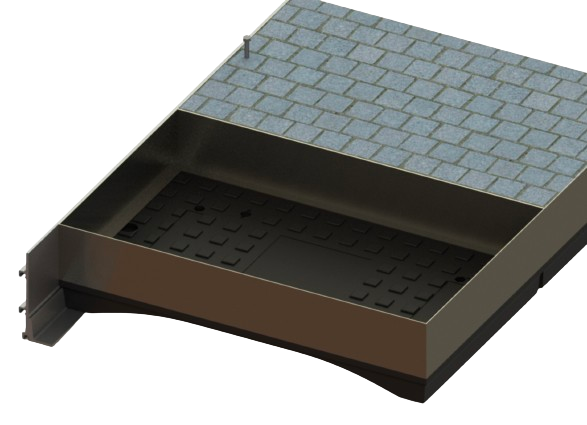

In-paved covers

Cast iron covers in the basic load classes are also used when the requirements for the uniformity of the cover design when installed in interlocking concrete pavement are met.

A higher version of the perimeter frame shall be used so that it is flush with the stainless steel trays, which can be paved with paving to 10 cm high. If lower paving is used, such paving shall be underlain by a layer of inert material to the required height.

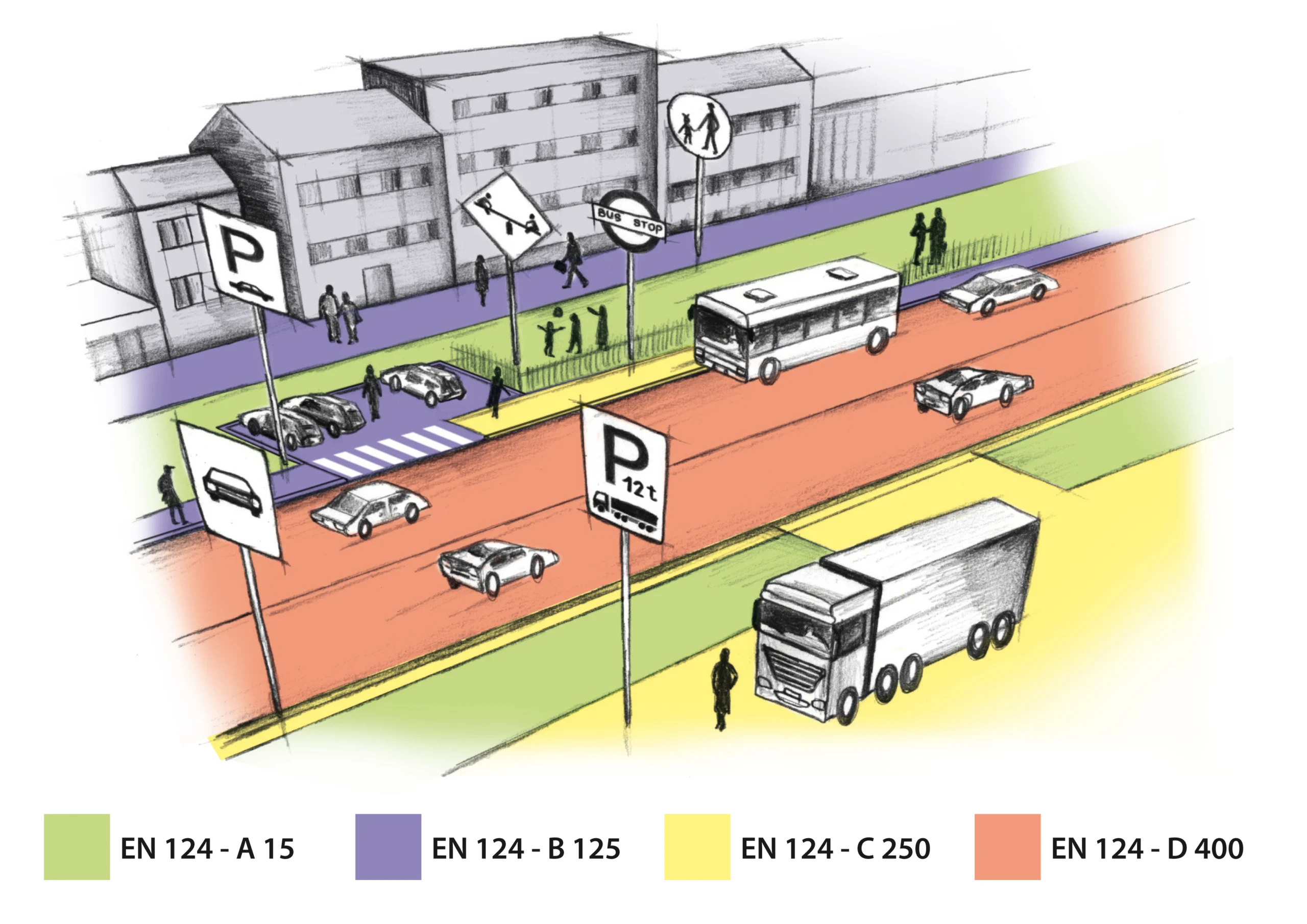

Loadability of ZEKAN coverscast iron cover load capacity

The distribution of the load capacity of covers and related structures is governed by EN 124, which distinguishes 6 load classes, marked with the letters A to F. The ZEKAN cable manholes system allows the use of the 2 most common load classes B125 (12.5 tonnes) and D400 (40 tonnes).

The suitability of the use of each type is described in the above mentioned standard. The choice of a given load class is to some extent the responsibility of the responsible designer, depending on the specific conditions of the cable manhole location. The following figure is for basic orientation only.

Advantages of cast iron covers:

Certificate cable manholes ZEKAN

Cable manholes ZAKAN - description

Dimensions of spacers

Cable duct installation technology using ZEKAN cable manholes

Drawings of parts cable manholes ZEKAN

Drawings cable manholes ZEKAN

PVC cable ducts ZEKAN - product sheet

Cable manholes - assembly procedure

Product sheet Cable manholes ZEKAN

DWG drawings cable manholes ZEKAN