News

Invitation to Oman Home and Build EXPO 2024

CWS s.r.o. cordially invites you to visit us at the international trade fair for construction, interior and exterior furnishings and architecture Oman Home & Building Expo 2024, where you can visit us at the stand with other Czech exhibitors.

Term: 7.-9. October 2024

Location: Oman Convention & Exhibition Centre, Muscat, Oman

Website: www.omanhome-building.com

The participation of the company CWS s.r.o. at the AMPER 2024

The 30th annual international trade fair AMPER.

From 19.3.2024 to 21.3.2024, CWS s.r.o. participated in the 30th anniversary edition of the AMPER trade fair. The fair was held in an area of 20 000 m2 in halls V and F at the Brno Exhibition Centre. Our stand was located in Hall V on the main corridor under number V 3.20. 410 exhibitors and more than 23 thousand professional visitors attended the fair.

We presented a wide portfolio of our products to our visitors, of which the greatest interest was in cable chambers, cable ducts including PVC pipes, ZEKAN cable trays and DEKAB cover plates and tapes.

It was a pleasure to meet our existing business partners as well as to make contact with potential new partners.

Thank you to all of you who visited our stand and showed interest in our products.

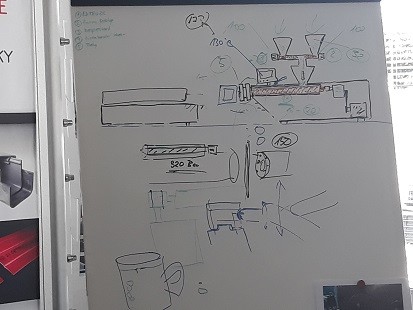

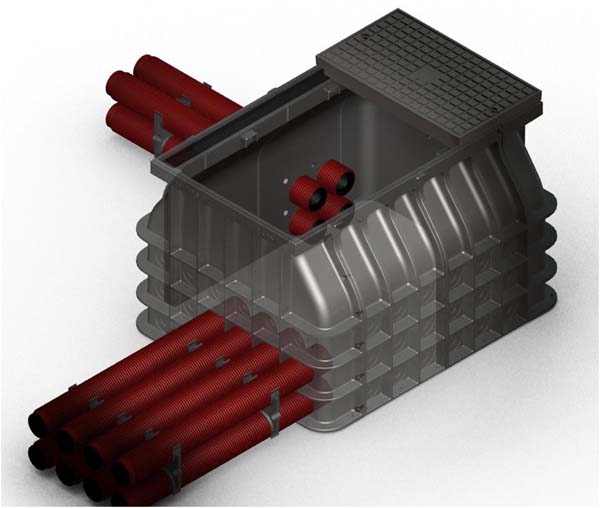

Modular system of Zekan cable chambers

In the past year the CWS s r.o. company introduced a modular system of cable chambers under the name Zekan. This year the Amper trade fair presents this system together with a comprehensive set of components and technical support for the components involved in the technical preparation and installation of these products

Development

In the development of cable chambers, state-of-the-art software tools have been used to design, construct and test products.

The entire design was made in a 3D environment to identify as accurately as possible the weaknesses of the entire design.

In this environment this model has been compared to the exact model, currently the most affordable equivalent of solution available in our market. The basic requirement for the solution itself was the significant exceeding all relevant parameters of the new system against the competitive solution.

By optimizing the shape of parts of the resulting solution, the 3D environment had more than 3 times the load capacity compared to the competition.

The finished models then served as a basis for mold design to ensure maximum precision and functionality of the entire cable chambers system. More information at: http://www.zekan.eu/wp-content/uploads/2012/02/Zekan-evolution-CZ.pdf

Both TUL in Liberec, as well as other capacities from specialists in the field of plastics technologies, statics of building structures and installation companies, actively participated in the development of the system design and the design of the used technology. Further cooperation is on the prepared system of Zekan multi-channels.

Innovation

Through technical solutions of the design of parts that are protected by the patent office, the system offers a wide scope for its use in its simplicity.

Support frame for placing the cover outside the walls of the cable chamber system components for the sub-concreting of the distributor ring for higher load classes.

Seated wall of the flange of the cable chamber inlet for the possibility of placing a steel profile for higher resistance of the assembly while maintaining the possibility of using standard covers.

Molded INSERTS with M12 thread for easy installation of additional assortment (DIN rails, footrests, load-bearing structures).

Pre-molded shape on the inner wall of the part to accommodate a standard steel profile, such as preventing wall deformation at high side pressure, etc.

More information at: http://www.zekan.eu/wp-content/uploads/2012/02/Zekan-innovation-CZ.pdf

Advantage

Standardization - only 4 basic parts and 4 modified covers according to the load class are sufficient to assemble any ZEKAN cable chambers from S to XXL type. This makes it easier to plan inventory, reduce storage and shipping costs by increasing the turnover of this product range and reducing total inventory resources (in comparison to less versatile solutions).

Systemability - for easy installation of cable pads up to a diameter of 110 mm (for larger diameters, shape parts are prepared) without disturbing the statics of the whole structure.

Possibility of selecting different types of protectors according to the requirements for strength, fire resistance and color.

Low transport costs - example: ZEKAN L 1080 set intended for transport:

Volume of the assembly put together - 1,38 m3

Assembly capacity ready for transport - 0,59 m3

More information at: http://www.zekan.eu/wp-content/uploads/2012/02/Zekan-benefits-CZ.pdf

In the framework of the support, a set of technical reports, assembly and installation procedures, technical solutions for non-standard installations, etc. are prepared and continuously updated, all for the maximum simplicity of choosing the right solution. More information at: http://www.zekan.eu/category/technicka-podpora/

CWS company staff are ready to respond to any query, request and demand.

Celebration of the 50th birthday of the CWS s.r.o. company owner.

The employees of CWS s.r.o. company congratulate the owner of the company to the Ing. Martin Mikš to his 50th birthday anniversary and wish him a lot of health, happiness and energy in the next years of production.

Lecture on extrusion to CWS s.r.o. employees

New CWS employees in production sessions will have 30 minutes of training on current production issues concerning extrusion lines.

These training courses will be carried out under the supervision of a production manager with many years of experience in the field of plastics industry. The first training was focused on extrusion functionality, and the employees praised the newly-acquired knowledge. We thank the lecturer Vladimir Martinc, who led the lecture.

Practice of students of Secondary Technical School in Ledec nad Sazavou

Thanks to the newly established cooperation with the Secondary Technical School in Ledec nad Sazavou, in our company we have accepted students for a two-week practice.

Thanks to the newly established cooperation with the Secondary Technical School in Ledec nad Sázavou, we have accepted our students for a two-week practice. Their acceptance was based on an evaluation of their marks, class teacher information, and master evaluations. Students were placed in production as a representative of the operator.

Their work is mainly line re-equipment, mold cleaning, production start-ups, work with measuring instruments, etc. However, for better involvement in the work process and the reality of work, students are involved in common work such as workplace cleaning, semi-finished workmanship, packing work, etc.

The students of this school are hardworking and we evaluate positively their work in our company. We hope to see even more interest in our offers next year.

CWS s.r.o. in the Ledec Newsletter

CWS s. r. o. In the Ledecky Newletter - article on the professional lecture of Vladimir Martinec and Ing. Kristynya Klikarova on the topic: Manufacturing Problems of New Technologies in Mechanical Engineering at the Manufacturing Company CWS s.r.o.

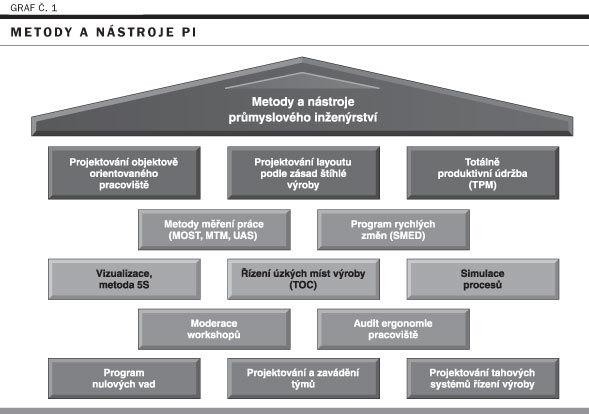

Industrial Engineering at CWS s.r.o. company

Nowadays, companies are exposed to more competitive environment than ever, and it is necessary to work on the company's internal structure, its strategy, to focus on shortening production time, reducing waste and increasing productivity. That's why our company started to apply industrial engineering methods to production.

The first method to be applied in our company is visualization and 5S method. The visual workplace is a structured, organized and managed workplace that has clearly defined all the processes that are there. This is why this method is hand-in-hand with the 5S method, which aims at making workplace waste more visible. Our company has decided to apply this method to one of its workplaces - shredding of poor quality products or rolls of material that originates in the process.

Cooperation with the Secondary Technical School in Ledec nad Sazavou

Our company has decided to support local students from the Secondary Technical School in Ledec nad Sazavou by providing practice for both apprenticeships for three years and for graduation years.

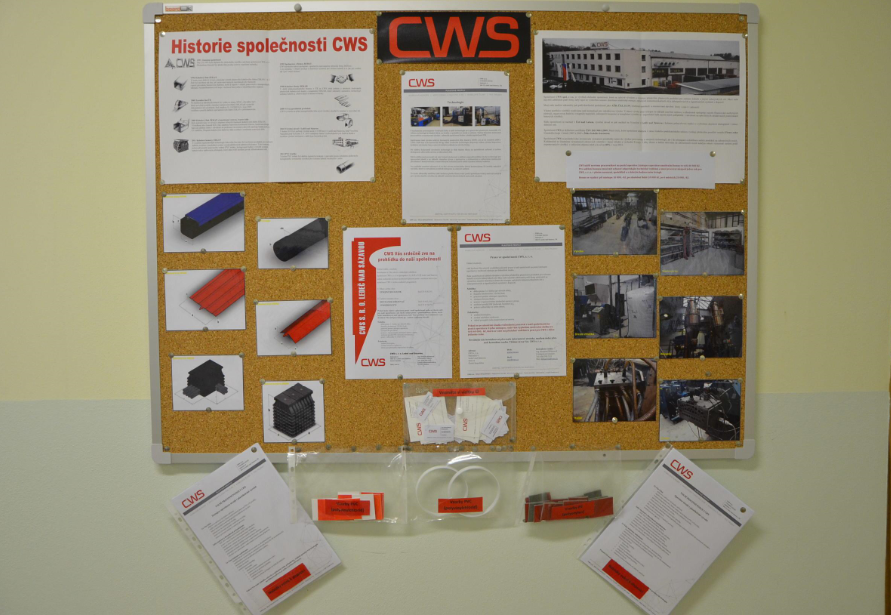

You can see information about our company from April in the building of the Secondary Technical School in Ledec nad Sazavou where we have placed a noticeboard with offers for students and their parents.

At the same time, our company prepared a lecture on plastic processing by extrusion and the use of Lean methods in manufacturing processes for third and fourth year students. Our students have been so interested in the lecture that they strarted to apply for professional practice.

Company of the year 2009

They appreciated education and a good idea in Ústí nad Labem.

Company of the year 2007

They appreciated education and a good idea in Ústí nad Labem.