Cable manholes Zekan

You have a question?

Contact usCable manholes Zekan

Plastic cable chambers are used as cable entry access points.

Cable manholes Zekan

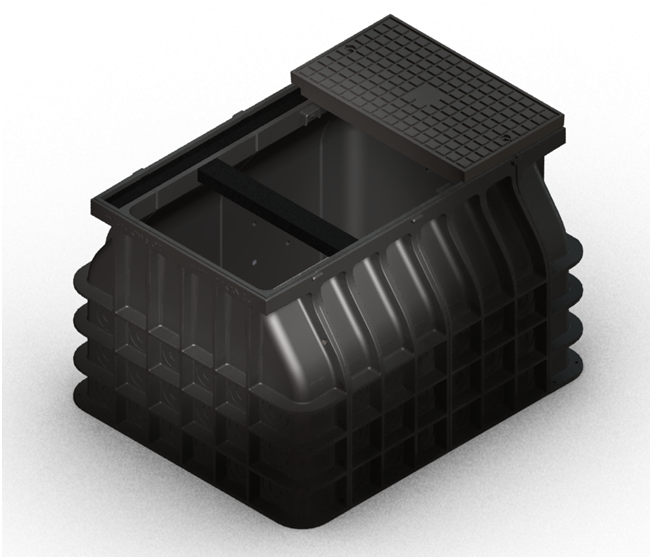

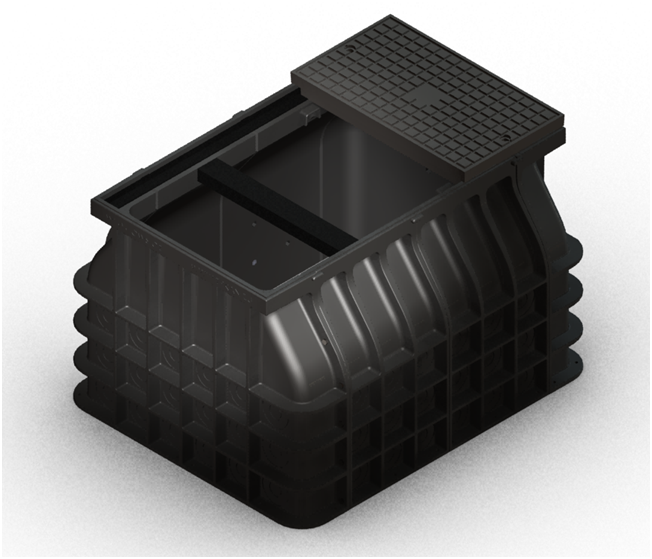

Plastic cable chambers are used as cable entry access points. Plastic cable chambers comparing to monolithic concrete or masonry shafts, are characterized by easy and quick installation, versatility of use and easier handling while maintaining the mechanical resistance requirements.

They are made of high density polyethylene (HDPE), which has very good mechanical properties. It is resilient, resistant to chemicals, easily machined (it can be machined with conventional metal and wood tools) and environmentally friendly. An advantage is the long life of the cable chambers, which is given by the used material for their production. ZEKAN chambers are a modular system that allows you to choose the size and depth of the chambers according to your requirements.

Cable manholes ZEKAN - a modern solution for IS management and protection

The state-of-the-art IS management and protection system at present is the use of plastic cable chambers along with durable plastic protectors that offer very good utility properties due to the lifetime of such built-in management systems and also because of low purchase prices.

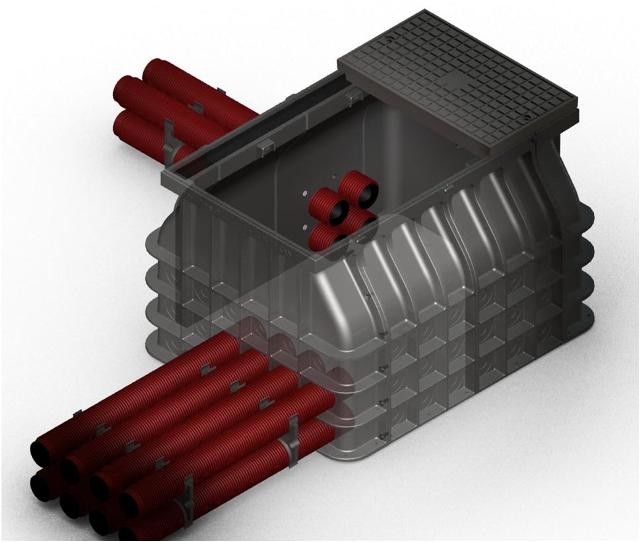

The interior of the shafts can be equipped with various accessories, depending on the customer's wishes - whether they are cable ladders, grates, legs or holders.

The current components for cable construction form a comprehensive system, allowing for a quick and convenient installation and greatly reducing the additional cost of such systems.

Modern systems offer a highly variable solution, whether for the construction of cable ducts according to given spatial options, as an alternative to collectors, multichannels or power channels.

The interior of the shafts can be equipped with various accessories, depending on the customer's wishes - whether they are cable ladders, grates, legs or holders.

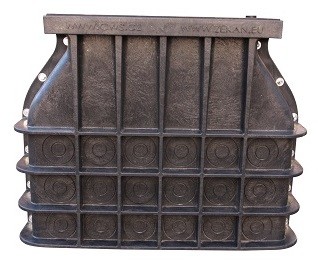

ZEKAN cable chambers are supplied with composite material covers in load class A 20 and B 125, which are stored in solid aluminum frames. The advantage of this design is lightness, easy handling, minimal maintenance and anti-theft prevention. Composite covers can be treated as a concrete imitation or in a pavement design (the cover is provided with a stainless steel frame).

For loading capacities in class B 125 and D 400, cast iron covers are stored in steel frames. These frames must be concreted during installation according to the installation instructions. For these covers, adapted chambers are provided to allow the concreting of the collar under the steel frame. The covers are designed for light operation in the D 400 class and must not be subjected to truck traffic.

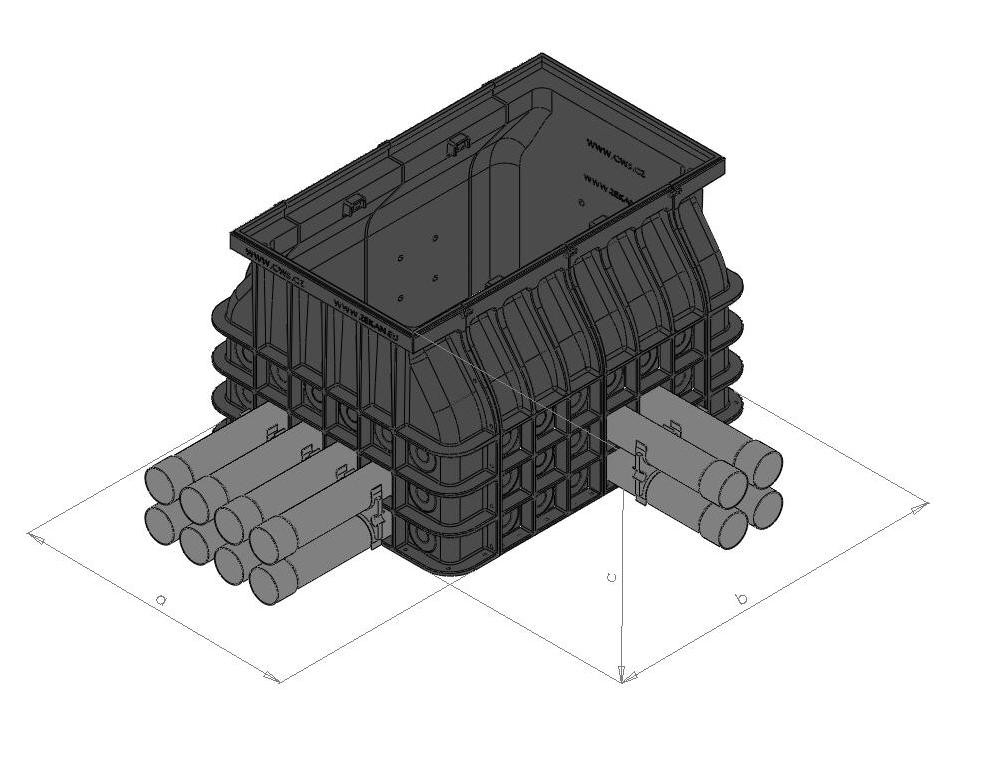

Only 4 basic parts and 4 types of covers according to the load class are enough to assemble any ZEKAN cable chamber from S type to XXL type. This makes it easier to plan inventory, reduce storage and shipping costs by increasing the turnover of this product range and reducing overall inventory resources.

| Basic information | ||

|---|---|---|

| Basic sizes | S, M, L, Xl, XXL | |

| Extended lower part | ZEKAN GRANDE | |

| Material | High density Polyethylen (HDPE - RE) | |

| Operating temperature | -30 °C ÷ + 50 °C | |

| Storage temperature | -25 °C ÷ + 55 °C | |

| Mounting temperature | -5 °C ÷ + 40 °C | |

| Guarabteed oridct kufe | 50 years | |

| Exological destruction | Recycling | |

| More information | Shades of black |

By default, the grooves for pipe outlets up to Ø 110 mm are preformed on the chamber parts. For the pipes of Ø 160 and Ø 200 mm, the lower part of the chambers can be fitted with parts for these diameters.

This is a modular system.

Basic chamber height: 800 mm

Basic height can be increased by adding parts - 280 mm superstructurs.

The installation and concreting of the chambers must be done according to static reports.

For designers

To support the design of the cable chamber system, we have prepared a static messages for all types of ZEKAN cable chambers in a reputable design office dealing with statics of underground structures were prepared, which enable a simplified design of a suitable chamber type for the solution. Part of this report also includes detailed assembly procedures. Just select the type of chamber, the required class according to the European standard EN 124 and together with the implementation and approval documentation include this file. In addition to the procedures according to EN 124 standard, the calculation and installation procedure for the storage of chambers on the railway according to the railway regulation SZDC S3 is also included in the report.

Development

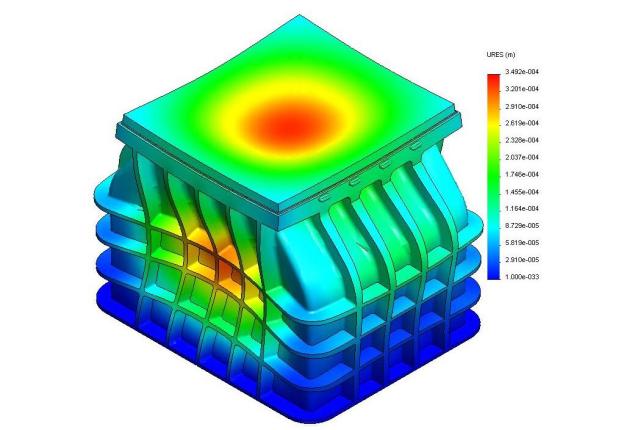

Within the framework of the development, the 3D model of the current, most commonly available cable chamber system, was precisely designed and constructed to compare the resistance of the assemblies with a constant static load load. The entire design was developed in a 3D environment so that it can be identified in the fase of weakness development of the whole system.

Unique resistance to deformation

Within the framework of the development, the 3D model of the current, most commonly available cable chamber system, was precisely designed and constructed to compare the resistance of the assemblies with a constant static load. The entire design was developed in a 3D environment so that it can be identified in the fase of weakness development of the whole system.

Another innovative system solution

The construction of ZEKAN cable chambers is the result of several years of communication with designers, assembly companies and IS builders. Thanks to this, the system offers several innovative technical solutions, some of them protected by the Patent Office:

- The support frame for the lid is outside the walls of the cable chamber system components for the possibility of underconcreting the distributor ring for the higher load capacity classe.

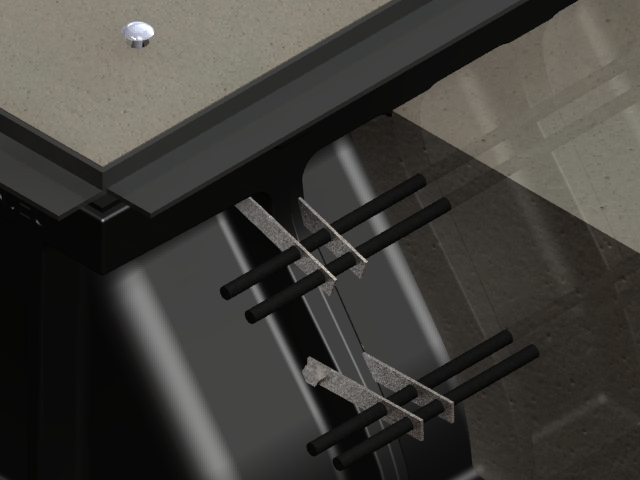

- Molded INSERTS with M12 thread for easy installation of additional assortment (DIN rails, footrests, load-bearing structures).

- Openings for connecting material M 10 are located close to ribs for maximum system strength.

- Circular support ribs reinforced to double (triple bond) of normal thickness for high structural load.

- The prescribed shape on the inner wall of the part to accommodate the standard steel profile as a prevention against wall deformation at high lateral pressure.

Standardizacion

Only 4 basic parts and 4 types of covers according to the load class are enough to assemble any ZEKAN cable chamber from S to XXL type. This makes it easier to plan inventory, reduce storage and shipping costs by increasing the turnover of this product range and reducing overall inventory resources.

Systemicity

The system is ready for easy installation of cable pads up to ø 110 mm (for larger diameters, shape parts are being prepared) without disturbing the statics of the whole structure. Possibility to select different types of protectors according to the requirements for strength, fire resistance, color.